Identifying Failures for Unparalleled Reliability

OVERVIEW

BENEFITS

KEY FEATURES

PLANS

CONTACT

OVERVIEW

INVESTIGATION MANAGEMENT SOLUTION

Developed as a simple, reliable Root Cause Analysis (RCA) tool, Investigation Optimizer™ offers a revolutionary way to manage incident reporting and continuous improvement in one centralized platform. Regardless of the investigation type (equipment, reliability, process, quality, HSE), every incident can be tracked and improved in the same location for visibility and efficiency when you need it most.

Featuring a Lean Six Sigma DMAIC process, Investigation Optimizer, the Best RCA software for industrial reliability, guides you and your team through systematic problem solving to standardize root cause thinking and reduce variability. With powerful integrations to bridge the gap between identifying failures and problem resolution, you can easily take control of your RCA investigations and ensure every incident results in improvement.

User Configurable

Cloud Based

EAM / CMMS Integration

Multi-user Access & Permissions

Driven by Email Communication

Customer Support

INVESTIGATION OPTIMIZER ANSWERS THE MOST COMMON QUESTIONS REGARDING YOUR ASSET’S RELIABILITY

I know we did an RCA on that same problem before, but who did it and where is it?

If everything is tracked manually, how can we get quantification in forms of monetary value or lost equipment and production time?

Operations always keeps their own check sheets & logos, but don't always report minor incidents or daily incidents into any reporting tool. What happens with them, stays with them?

How can we identify our bad actors if we are busy with so many other tasks?

Sometimes actions don't follow through because there is no tracking or accountability system. How can avoid having the same issue again?

How much is downtime costing us?

BENEFITS

Engage teams and leadership in a step-by-step process of Lean Six Sigma DMAIC problem-solving

Streamline Incident Reporting, RCA Investigations, and Continuous Improvement to eliminate wasted process, time, and money

Capture every incident against an asset hierarchy for easy analysis and resolution of repeating problems

Generate actionable insights to reduce unplanned downtime, increase production throughput, and minimize quality/safety issues

Improve OEE/Reliability with a complete Failure Reporting, Analysis, and Corrective Actions system

KEY FEATURES

Investigation Optimizer provides many features and functions to track the implementation and effect of a recommendation to prove the recurring problem has been eliminated or indicate that further actions/analysis must be taken.

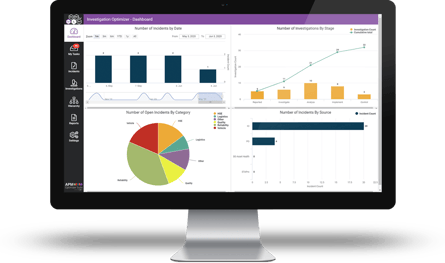

INTERACTIVE DASHBOARD

An interactive dashboard is part of what makes Investigation Optimizer the best RCA software for industrial reliability. The dashboard displays a quick snapshot of all active incidents and investigations to increase visibility for both teams and leaders. Email notifications/alerts ensure the right people are kept engaged and informed throughout the entire process.

Easily import/integrate Asset Hierarchies to directly relate an incident to an asset. Customizable reports emphasize visual management of actions for investigations, recommended actions, and approvals.

DMAIC ROOT CAUSE ANALYSIS (RCA)

DMAIC RCA provides a step-by-step guide to problem solving using a complete Failure Report, Analysis, and Corrective Action system. Visually display and identify the root cause with easy escalation from a simple 5 Whys to more complex Cause Map.

Determine an incident’s risk as it relates to an organization’s Risk Matrix and quickly review any mitigations against its Failure Mode libraries. Proactively determine the root cause of potential failures and take the necessary actions to prevent it.

ADDITIONAL FEATURES

User Configuration/Management

Automated Email Notifications/Reminders

Customizable Risk Matrix

End-to-End Investigation Control and Reporting

Condition Monitoring, Asset Health, and Work Execution Software Issues/Alerts

Easy Escalation – simple 5 Whys to complex Cause Map

Seamless connection with APM Optimizer Suite™

PLANS

Core FeaturesCompare package features

- Unlimited Users & Team

- Unlimited Investigations

- User Management

- Historical Incident Records

- 5 Step DMAIC RCA Process

- Corporate Structure Capability

- Integrations*

- Risk Management/Mitigation

- Customizations*

- Storage

30 DAY FREE TRIAL

All trials include 100% functionality and access to Business Plan features.

*Capability exists/additional fee for added feature.

All FeaturesCompare package features

- Core Features

- Unlimited Users & Team

- Unlimited Investigations

- User Management

- Historical Incident Records

- 5 Step DMAIC RCA Process

- Corporate Structure Capability

- Integrations*

- Risk Management/Mitigation

- Customizations*

- Storage

- Define

- Incident Reporting

- Investigation Parameters

- Import from Connected Systems*

- Investigate/Measure

- Equipment Issues/Failures

- HSE (Accidents/Spills/Illness)

- Quality

- Attach Evidence/Documents/Pictures

- View/Assign Incidents Against Asset Hierarchy

- Analyze

- 5 Why Charting

- Fishbone Diagram

- Cause Map/Line of Sight

- Structured Failure Mode (Develop/Assign)

- Risk Matrix (Customizable)

- Implement

- Suggest New Maintenance Strategies

- Initiate Maintenance Strategy Modifications

- Submit Unlimited Implementation Actions

- Action Management/Tracking

- Follow-Up Actions

- Control

- Future Follow Up/Control Function

- Implemented Actions

- A3 Report

- Closeout Investigations

Lite$1.99USD/MO

START FREE TRIAL

- Includes 1 | $1.99USD/add. user

- 1GB

- Includes 1 | $19.99USD/add. user

- 10GB

Enterprise CONTACT SALES

CONTACT US

- Additional Users Included

- UNLIMITED

30 DAY FREE TRIAL

All trials include 100% functionality and access to Business Plan features.

*Capability exists/additional fee for added feature.

CONTACT US

You may also be interested in:

Arab Gateway Port and Transshipment Hub Selects Nexus Global as APM Training Provider

Nexus Global was awarded a long-term training contract to support a major Omani seaboard shipping port as they continue efforts towards achieving world-class operational...

Asset Performance Management | More Than Just Implementing EAM

Defining APM: Gartner defines Asset Performance Management (APM) as encompassing the capabilities of data capture and cleansing, integration, visualization, and...

DMAIC RCA: A Proven Approach to Reliability

What is DMAIC RCA? DMAIC, pronounced “duh-may-ik," is a data-driven approach to problem-solving designed to identify and improve existing process inefficiencies with unknown...

Best Practices - Asset Management, ISO 55000, Industry 4.0

On this episode, Larry talks withPilar Valderrama, Asset Management Technology Manager for Stork-Flour, about her mission to bring Asset Management and ISO 55000 to Latin...

Tying Risk/Investigations/Root Cause Analysis (RCA) Together

More than 50% of the process industry is still operating with paper or file-based maintenance systems and people dependent processes for Root Cause Analysis (RCA). In today's...

The 3 Most Popular RCA Tools

Unfortunately when it comes to life and reliability. there isn't a crystal ball and unpredicted problems can occur in any team or process. However, problems are just symptoms of...

.png?width=415&height=308&name=Login-Mon%20(1).png)